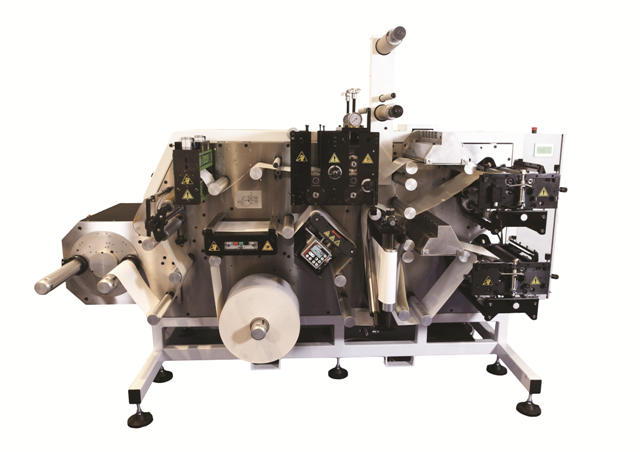

LESKO RLS280PRN

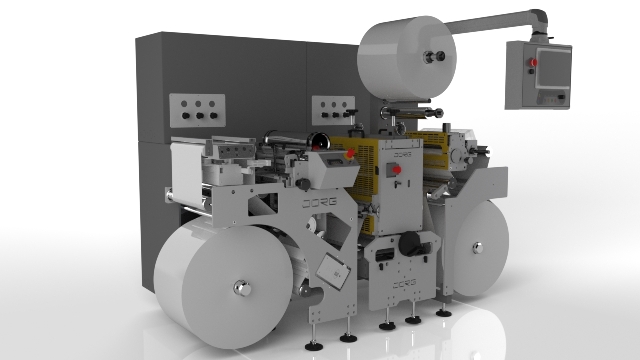

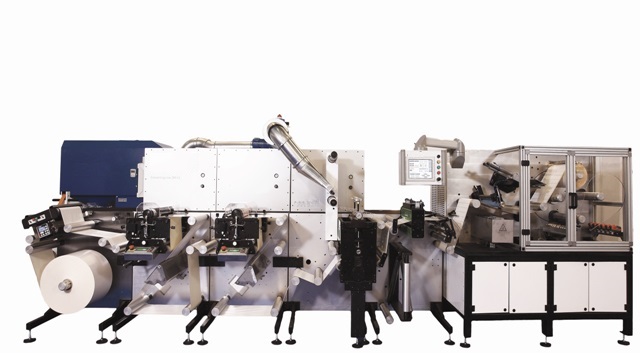

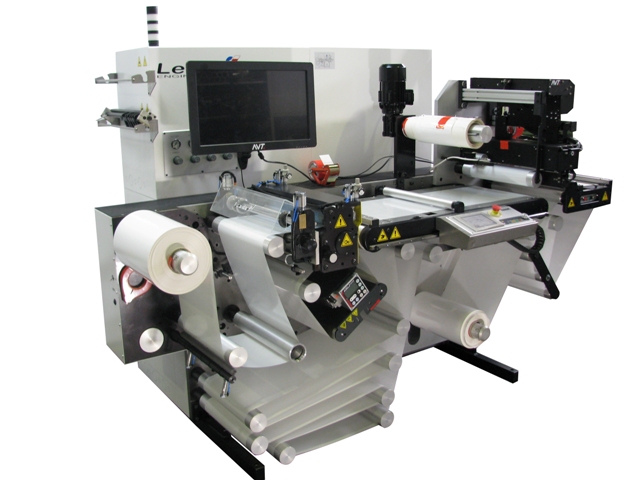

LESKO RLS280PRN is the only one on the market so compact and multifunctional machine designed for printing and confectioning of labels.

The machine can be equipped with a rotary die cutting unit and the dual printing unit.

Usage of servo mechanism ensures off-line die cutting in register.

Additionally, there is possibility to use servo mechanism in one of printing units, which allows to print the third color.

FEATURES AND OPTIONS

TECHNICAL DATA:

- max. web width 280 mm

- max. speed (winding/die cutting) 220 m/min

- max. speed (printing) 110 m/min

- max. unwinding diameter Ø 750 mm

- unwinder and rewinder pneumatic spindle Ø 76 mm

- max. rewinding diameter on single spindle Ø 440 mm

- max. rewinding diameter on dual spindle Ø 310 mm

- max. rewinding diameter on dual spindle – option Ø 600 mm

- power supply voltage 3x400 V

- frequency 50 Hz

- installed power (standard) 6 kW

- average air requirement 1 m3 ; 6 bar

- weight (standard) ` 900 kg

- size (standard) (L x W x H) 1650 x 1250 x 1950 mm

control:

- microprocessor control

- tactile panels with intuitive interface

- control panel + operator panel near the web-connecting table

motors:

- asynchronous motor - the main drive

- asynchronous motor - rewinder(s) drive

- powder brake on the unwinder

- powder clutch on a rewinder

opctional:

- servo motor on rewinder:

- very precise tension control

- rewinding materials with specific parameters, eg. foils

- rewinding rolls with diameters Ø 600 mm

- servo motor on unwinder:

- active compensation of tension during acceleration and braking

- servo motor on rotary die cutting unit:

- off-line die cutting to register

- servo motor on flexo printing unit:

- enabling printing of third colour

sensors:

- current meters and labels electronic counter

- luminal sensor

- five-line missing labels control system

- ultrasonic sensor of end of the roll with automatic stop

optional:

- US sensor for transparent labels

- sensor for detecting the flags

UNWINDER:

- max. roll diameter 750 mm

- max. lifting capacity 100 kg

- pneumatic expansion spindle Ø 76 mm

- electromagnetic (powder) brake

WEB-CONNECTING TABLE:

- equipped with pneumatic clamp blocks, thanks to which the tension of the material is retained during webs repairing

WEB MOTION:

- BST web guide system with smooth control

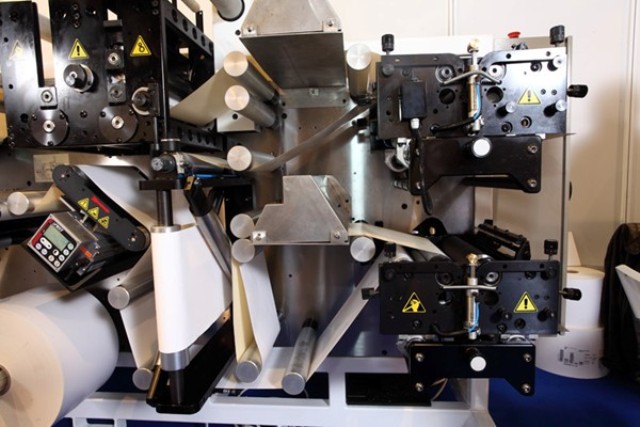

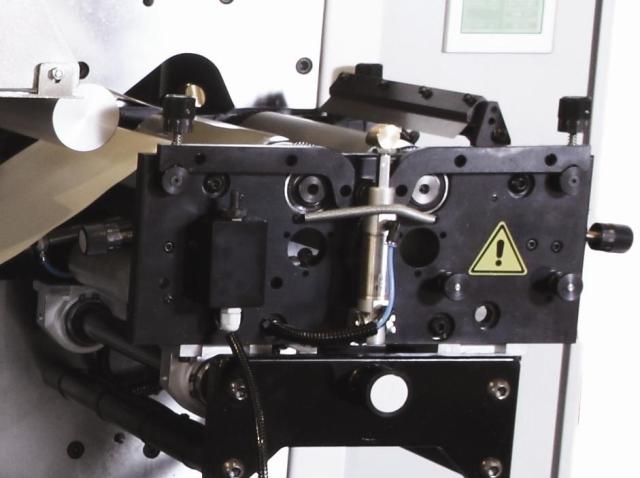

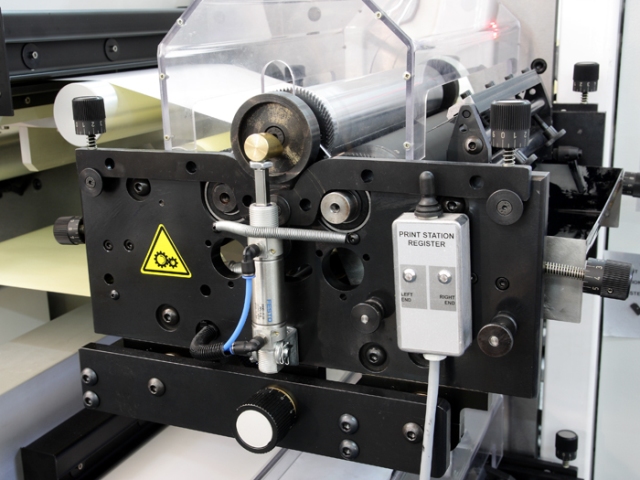

FLEXO PRINTING UNIT:

- max printing width 270 mm

- lateral shift adjustment +/- 7 mm

- longitudinal shift adjustment +/- 15 mm

- duct roller

- anilox grid raster 160L / cm, 60 ° 6,5cm3 / m2

- rotating anilox during standstill

- IR dryer 3000W with the side waste exhauster and power controlled automatically depending on speed

optional:

- second flexo printing unit

- additional servo motor enabling printing of third colour

- single UV lamp from UV-ray or GEW; maximum power: 160W / cm (fan, power supply unit, operator panel)

- double UV lamp from UV-ray or GEW; maximum power: 160W / cm (2x fan, 2x power supply unit, 2x operator panel)

NIP-ROLL:

- pneumatic clamp

- easy replacement and cleaning of rubber roller

SHEAR CUTTING KNIVES UNIT:

- knives for scissor system cutting

- 3 sets of knives + the possibility to add following

- min. cutting width 10 mm

REWINDER:

- max. winding diameter Ø 440 mm

- pneumatic expansion spindle Ø 76mm

- electromagnetic (powder) clutch

- change the winding direction from the control panel

optional:

- additional rewinder (max. winding diameter - Ø 310 mm)

- special rewinders system for rewinding rolls with diameters Ø 600 mm (servo motor)

- spindles with diameters from Ø 19 to Ø 76mm

- adapters for spindles with diameters from Ø 76 to Ø 152 mm

- semi-turret version of rewinders with the option of simultaneous wound on two spindles

ADDITIONAL EQUIPMENT:

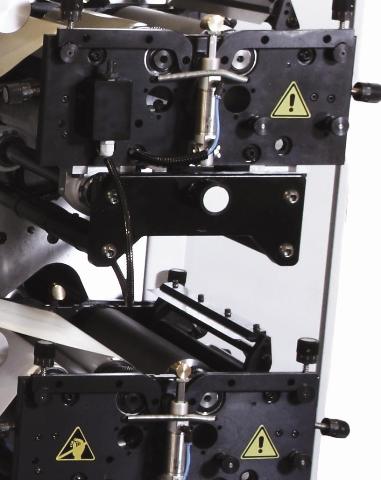

ROTARY DIE CUTTING UNIT:

-

- max. working width of cylinder 280 mm

- max. circumference of cylinder 125 T/1/8”

- adapted to constant, long-term work

- anvil supported by the driven shaft

- gap control system GapMaster from Kocher+Beck

-

optional:

-

- any gap control system offered in the market

- the hydraulic pressure control system of the magnetic cylinder

- adapters for other magnetic cylinders

- adaptation of the whole die cutting unit for customer's cylinders

- work off-line in register

- possibility of convertion of cylinder and anvil to perform the perforation of the base

WASTE MATRIX REWINDER:

-

- max. roll diameter 500 mm

- mechanical spindle Ø 76 mm

-

optional:

-

- pneumatic spindle Ø 76 mm

WEB INVERTING UNIT BETWEEN PRINTING UNITS:

-

- enabling printing on the other side of the material

- stroboscope synchronized with the speed of machine

- pneumatic clamp of the end of web controlled from the operator panel

- single foot switch to control the machine: working at jog speed

- dual foot switch to control the machine: working at jog speed + switching on compressed air

- razor blade knives unit:

- 5 knives + possibility to add following

- pneumatic crush cutting knives unit:

- 3 knives + possibility to add following

- at nip-roll place

- additional rewinder's expansion spindles:

- diameters: Ø 25 mm, Ø 40 mm, Ø 50 mm, Ø 76 mm

- the side waste exhauster

- rotary sheeting unit:

- at nip-roll place

- cuvette for receiving sheets or a small receiving table or a large sorting-receiving table