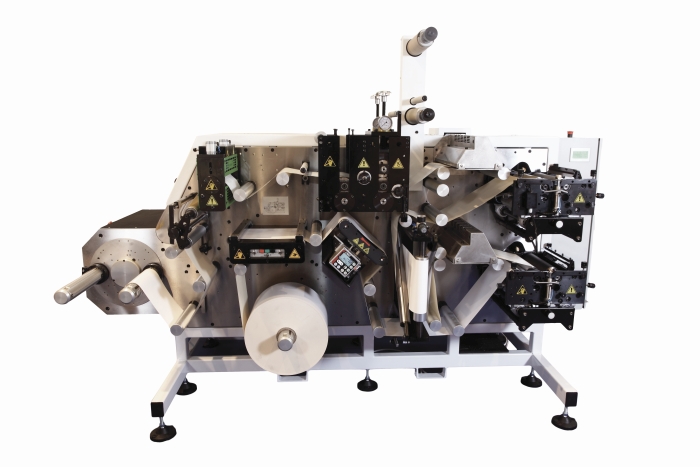

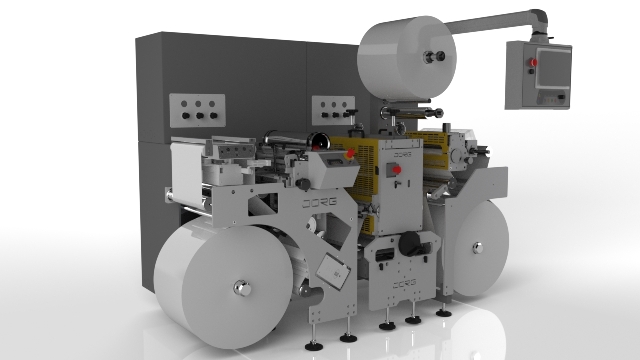

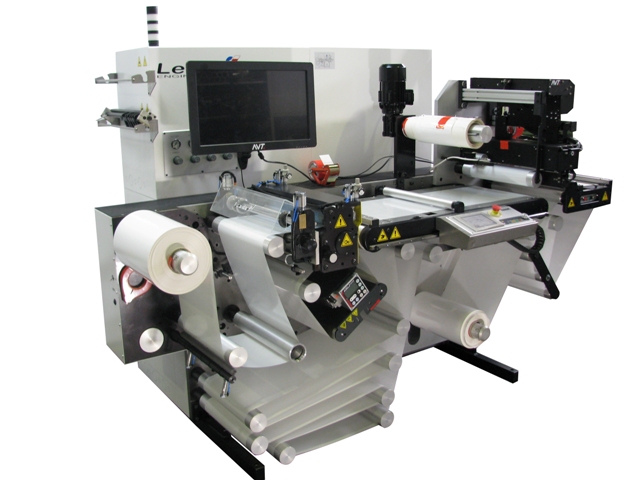

LESKO RLS DIE

LESKO RLS DIE is the optimally constructed, ideal die cutting machine for constant, long-term work, even 24/7.

This type of machine can be used to:

- die cutting,

- confectioning on the specified number of labels or roll length,

- slitting.

Our die cutting machines type RLS DIE are dedicated to work with printed and pure materials.

Thanks to long-term experience we can offer you a machine with the latest generation die cutting unit.

Optimum structure of die cutting unit (anvil supported by resistance shaft ) ensures stability of parameters for many years.

FEATURES AND OPTIONS

TECHNICAL DATA:

| Technical data: | ||||

| web width | 280 mm | 380 mm | 440 mm | 530 mm |

| max. speed | 220 m/min | 220 m/min | 220 m/min | 220 m/min |

| max. unwinding diameter | 750 mm | 750 mm | 750 mm | 750 mm |

| unwinder and rewinder pneumatic spindle | Ø 76 mm | Ø 76 mm | Ø 76 mm | Ø 76 mm |

| max. rewinding diameter on single spindle | Ø 440 mm | Ø 440 mm | Ø 440 mm | Ø 440 mm |

| max. rewinding diameter on dual spindle | Ø 310 mm | Ø 310 mm | Ø 310 mm | Ø 310 mm |

| max. rewinding diameter on dual spindle - optional | Ø 600 mm | Ø 600 mm | Ø 600 mm | Ø 600 mm |

| power supply voltage | 3x400 V | 3x400 V | 3x400 V | 3x400 V |

| frequency | 50 Hz | 50 Hz | 50 Hz | 50 Hz |

| installed power | 4,5kW | 9,5kW | 9,5kW | 9,5kW |

| average air requirement | 1 m3 ; 6 bar | 1 m3 ; 6 bar | 1 m3 ; 6 bar | 1 m3 ; 6 bar |

| weight | 750 kg | ok 1050 kg | ok 1050 kg | ok 1050 kg |

| size (L x W x H) | 1650 x 1250 x 1950 mm | 2150 x 1350 x 1950 mm | 2150 x 1450 x 1950 mm | 2150 x 1550 x 1950 mm |

control:

- microprocessor control

- panels with simple and intuitive interface

- control panel with touchscreen + operator panel near the web-connecting table

motors:

- asynchronous motor - the main drive

- asynchronous motor - rewinder(s) drive

- powder brake on the unwinder

- powder clutch on a rewinder

optional:

- servo motor on rewinder:

- very precise tension control

- rewinding materials with specific parameters, eg. foils

- rewinding rolls with diameters Ø 600 mm

- servo motor on unwinder:

- active compensation of tension during acceleration and braking

- servo motor on rotary die cutting unit:

- off-line die cutting to register

sensors:

- current meters and labels electronic counter

- luminal sensor

- five-line missing labels control system

- ultrasonic sensor of end of the roll with automatic stop

optional:

- US sensor for transparent labels

- sensor for detecting the flags

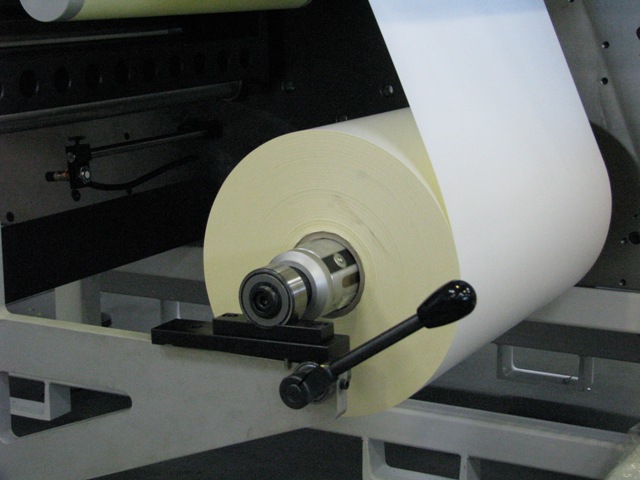

UNWINDER:

| web width | 280 mm | 380 mm | 440 mm | 530 mm |

| max. roll diameter | 750 mm | 750 mm | 750 mm | 750 mm |

| max. lifting capacity | 100 kg | 120 kg | 140 kg | 160 kg |

| pneumatic expansion spindle clamping from the panel | Ø 76 mm | Ø 76 mm | Ø 76 mm | Ø 76 mm |

|

electromagnetic brake |

powder | powder | powder | powder |

| transport rollers for easy loading of heavy rolls | no option | option | standard | standard |

WEB-CONNECTING TABLE:

- equipped with pneumatic clamp blocks, thanks to which the tension of the material is retained during webs connection

WEB MOTION:

- BST web guide system with smooth control

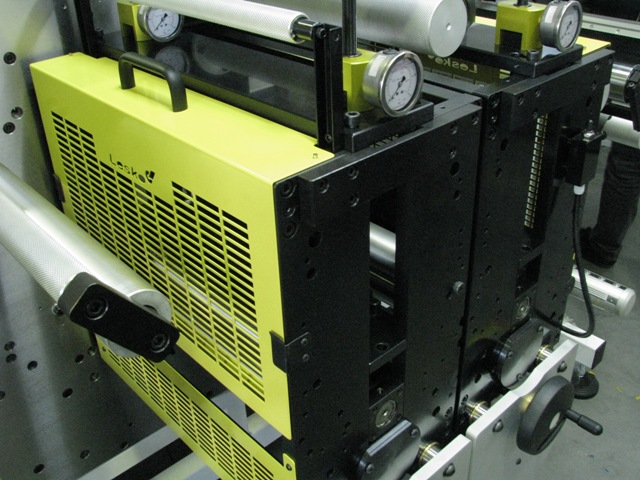

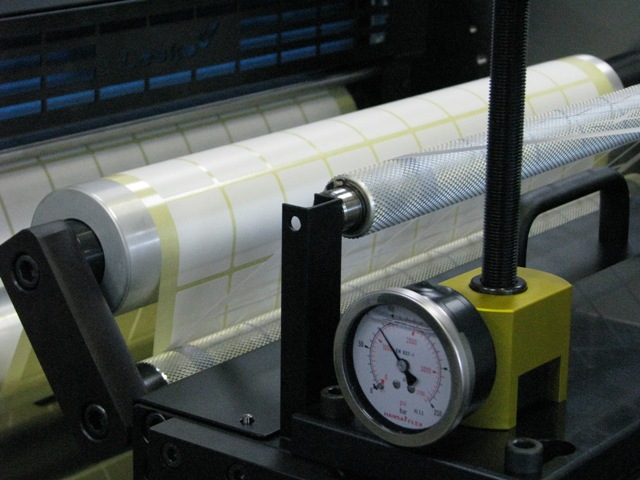

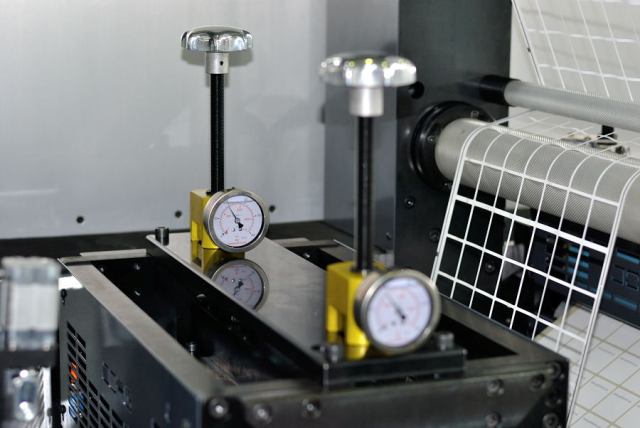

ROTARY DIE CUTTING UNIT:

| web width | 280 mm | 380 mm | 440 mm | 530 mm |

| max. working width of cylinder | 280 mm | 380 mm | 440 mm | 530 mm |

| max. circumference of cylinder | 125 T / 1/8” | 200 T | 200 T | 200 T |

-

adapted to constant, long-term work

- optimal, highly durable construction (anvil supported by the driven shaft)

- gap control system GapMaster from Kocher+Beck

- easy and precise transverse adjustment

optional:

- additional rotary die cutting unit with the same parameters (possibility of convertion of cylinder and anvil to perform the perforation of the base)

- die cutting unit with the option of sheeting

- any gap control system offered in the market

- the hydraulic pressure control system of the magnetic cylinder (precision and safety)

- adapters for other magnetic cylinders

- adaptation of the whole die cutting unit for customer's cylinders

- work off-line in register

WASTE MATRIX REWINDER:

- max. roll diameter 500 mm

- mechanical spindle Ø 76 mm

optional:

- pneumatic spindle Ø 76 mm

- max. roll diameter 600 mm

- clamp on matrix rewinder

NIP-ROLL:

- pneumatic clamp

- easy replacement and cleaning of rubber roller

SHEAR CUTTING KNIVES UNIT:

- knives for scissor cutting system

- 3 sets of knives + the possibility to add following

- min. cutting width 10 mm

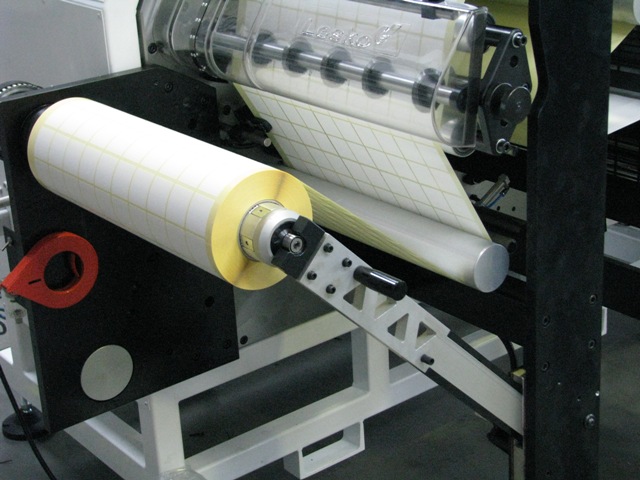

REWINDER:

- max. winding diameter Ø 440 mm

- pneumatic expansion spindle Ø 76mm

- electromagnetic (powder) clutch

- change the winding direction from the control panel

optional:

- additional rewinder (max. winding diameter - Ø 310 mm)

- special rewinders system for rewinding rolls with diameters Ø 600 mm (servo motor)

- spindles with diameters from Ø 19 to Ø 76mm

- adapters for spindles with diameters from Ø 76 to Ø 152 mm

- semi-turret version of rewinders with the option of simultaneous wound on two spindles

ADDITIONAL EQUIPMENT:

- prolonged course of web for inspection

- stroboscope synchronized with the speed of machine

- pneumatic clamp of the end of web controlled from the operator panel

- single foot switch to control the machine: working at jog speed

- dual foot switch to control the machine: working at jog speed + switching on compressed air

- razor blade knives unit:

- 5 knives + possibility to add following

- pneumatic crush cutting knives unit:

- 3 knives + possibility to add following

- at nip-roll place

- additional rewinder's expansion spindles:

- diameters: Ø 25 mm, Ø 40 mm, Ø 50 mm, Ø 76 mm

- the side waste exhauster

- rotary sheeting unit:

- at nip-roll place

- cuvette for receiving sheets or a small receiving table or a large sorting-receiving table