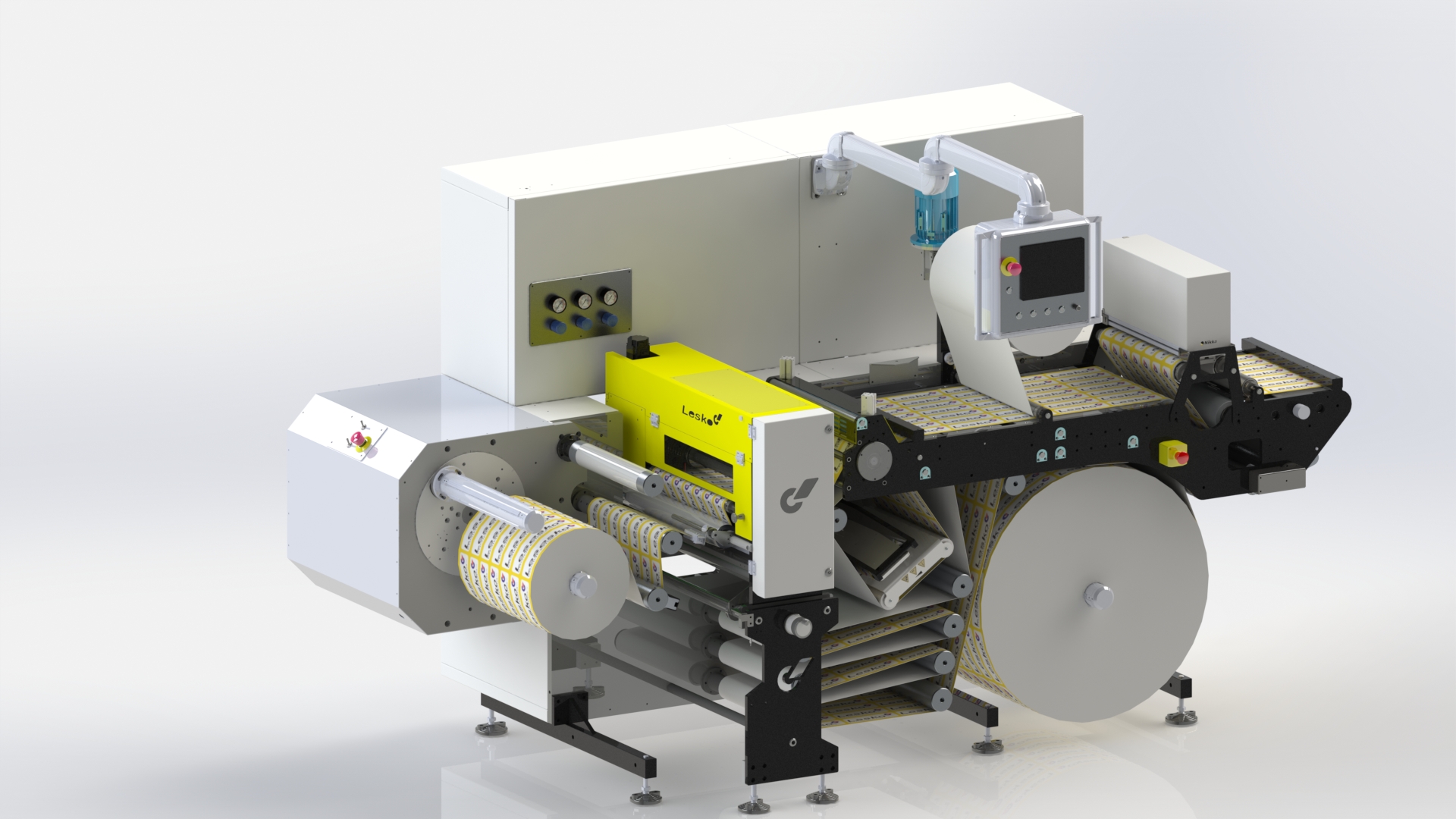

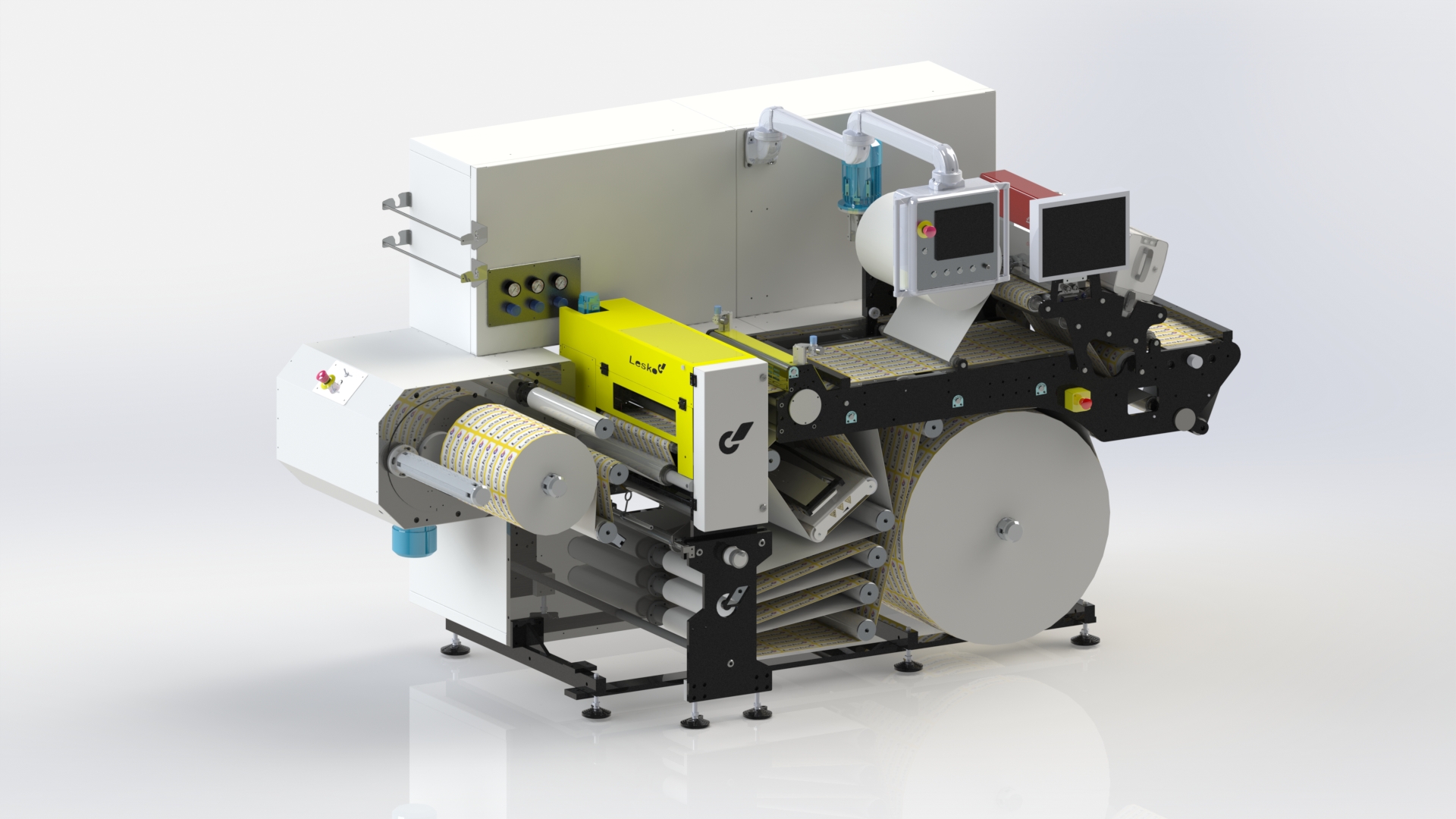

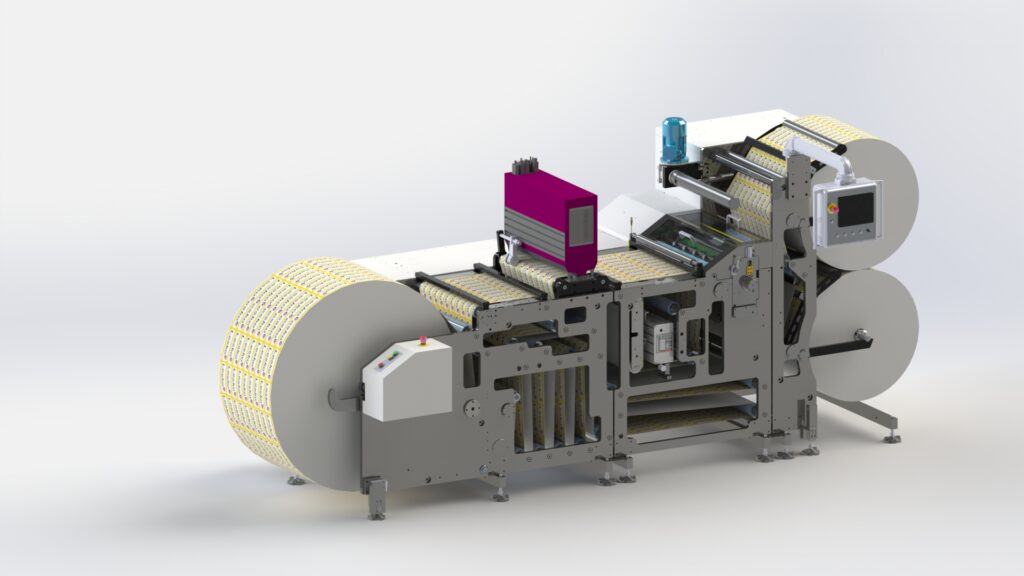

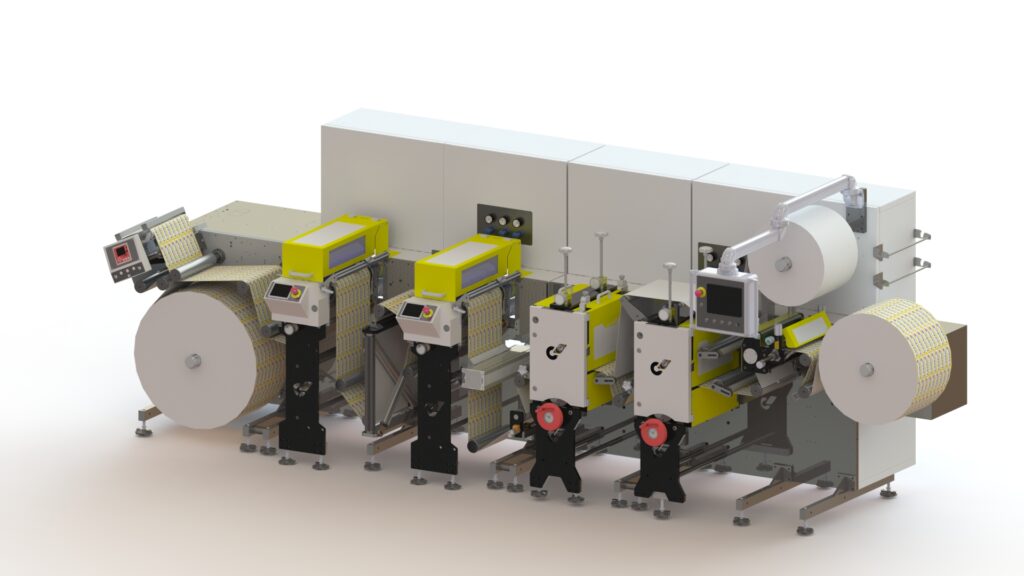

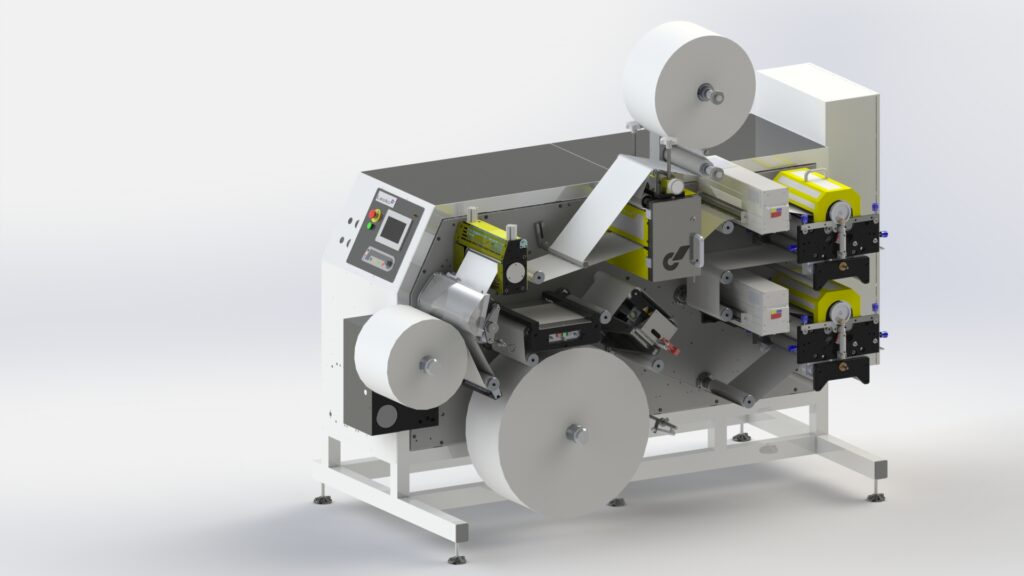

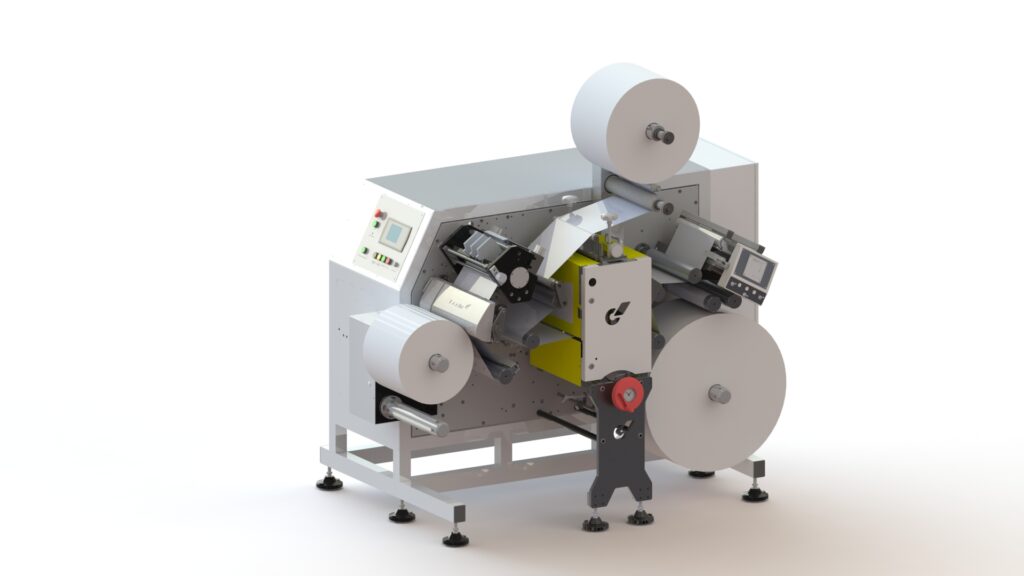

LESKO HI440

Inspection machine LESKO HI440 is dedicated to work with the previously prepared materials. The machine is ideally suited for:

- printed materials confectioning,

- precise slitting.

- inspection.

Our idea of inspection system fully integrated with the machine guarantees 100% control of printing quality and maintain very high efficiency.

FEATURES AND OPTIONS

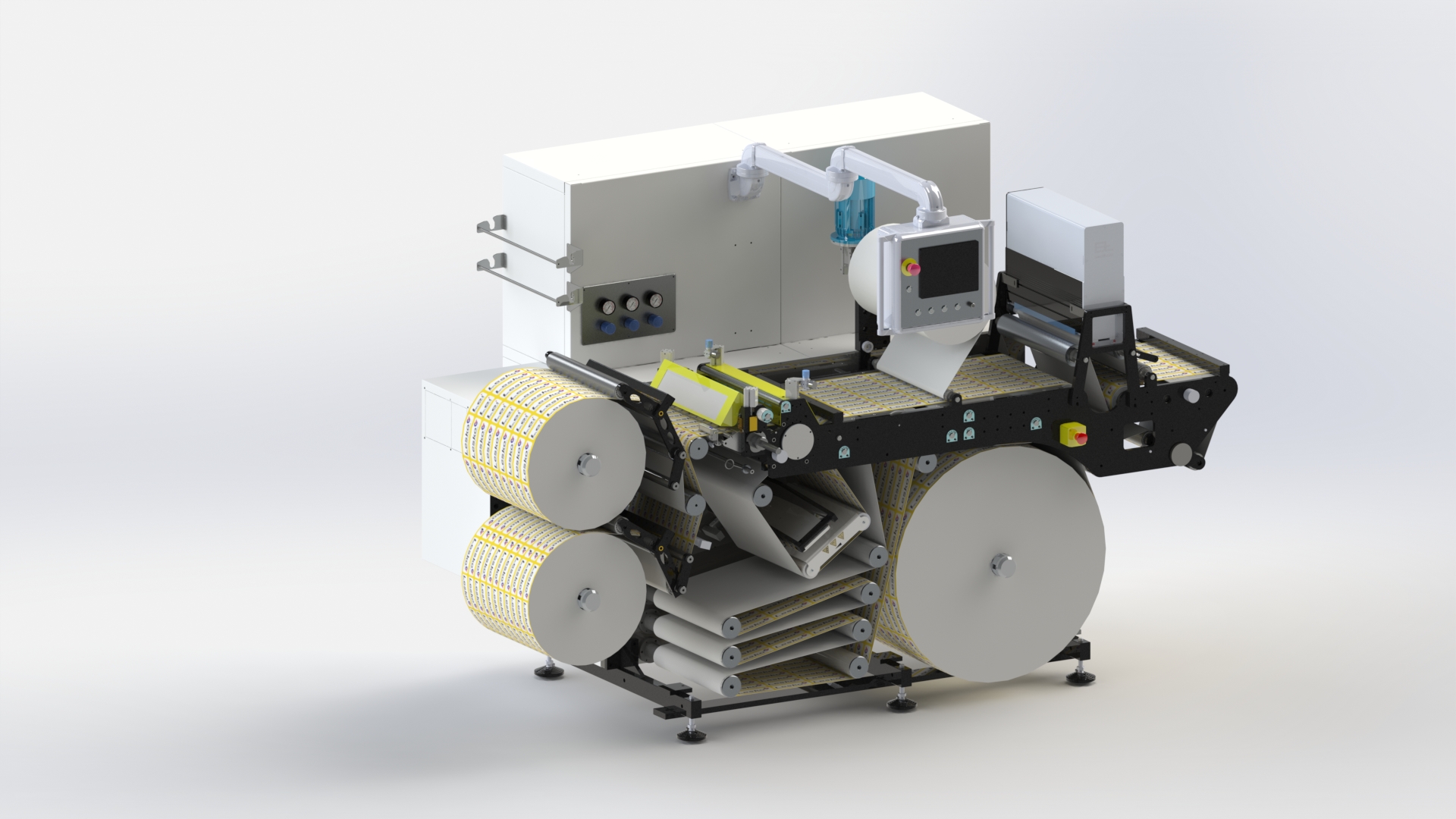

TECHNICAL DATA:

- max. web width 440 mm

- max. speed 400 m/min

- max. unwinding diameter 800 mm

- max. lifting capacity 160 kg

- unwinder and rewinder pneumatic shaft Ø 76 mm

- max. rewinding diameter on single shaft Ø 1 x 600 mm

- max. rewinding diameter on double shaft Ø 2 x 600 mm

- power supply voltage 3 x 400 V

- frequency 50 Hz

- installed power ~8 kW

- average air requirement ~1 m3 ; 6 bar

- weight ~1000 kg

- size of type 440 (L x W x H) 2400 x 1500 x 1750 mm

control:

- microprocessor control

- touchscreen control panel 7" with intuitive interface

motors:

- AC motor - the main drive

- powder brake on the unwinder

- servo motor or electromagnetic clutch on each rewinder

optional:

- servo motor or AC motor on unwinder (active compensation of tension during acceleration and braking)

sensors:

- meters and labels electronic counter

optional:

- US sensor for transparent labels

- sensor for detecting the flags

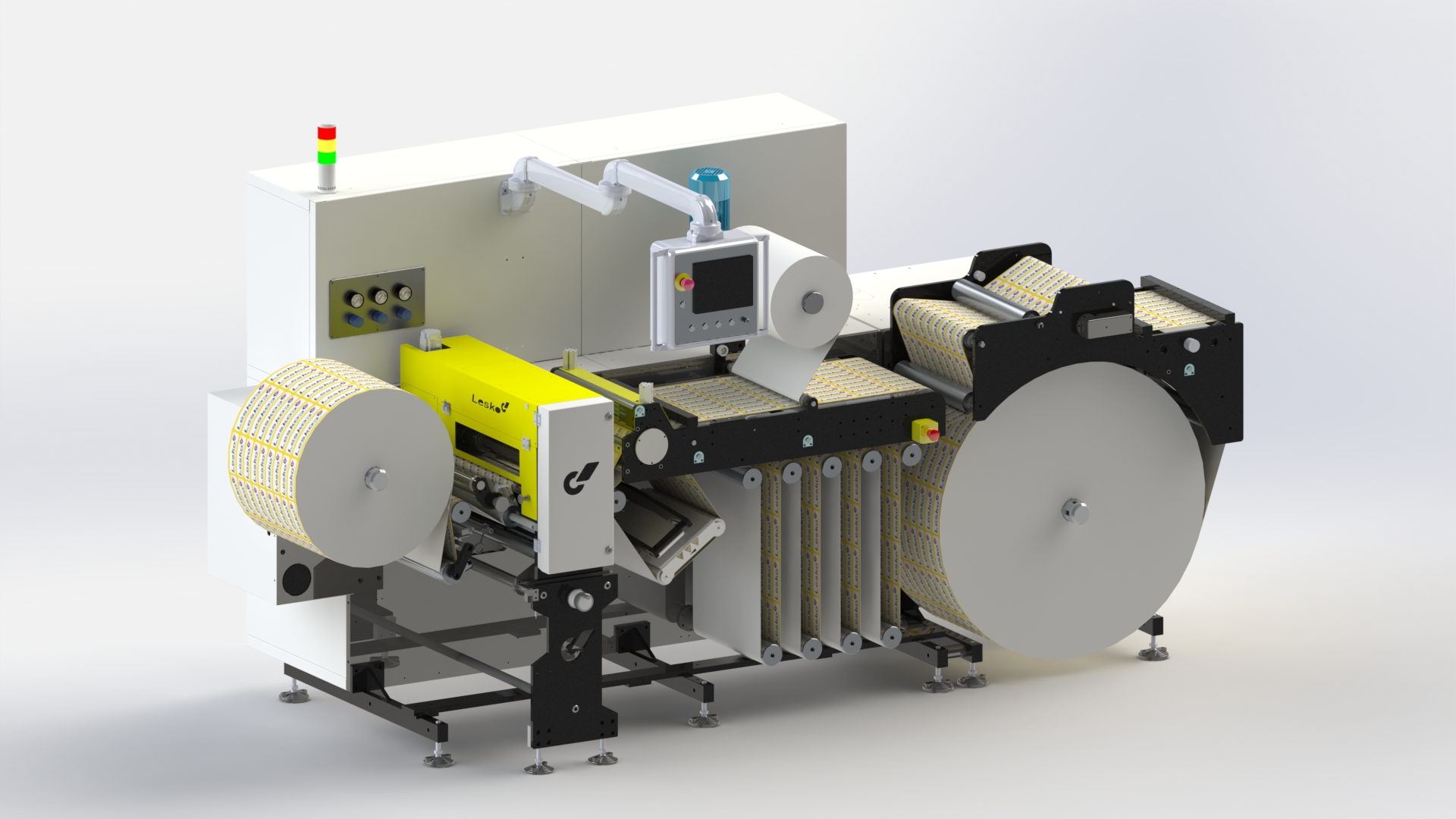

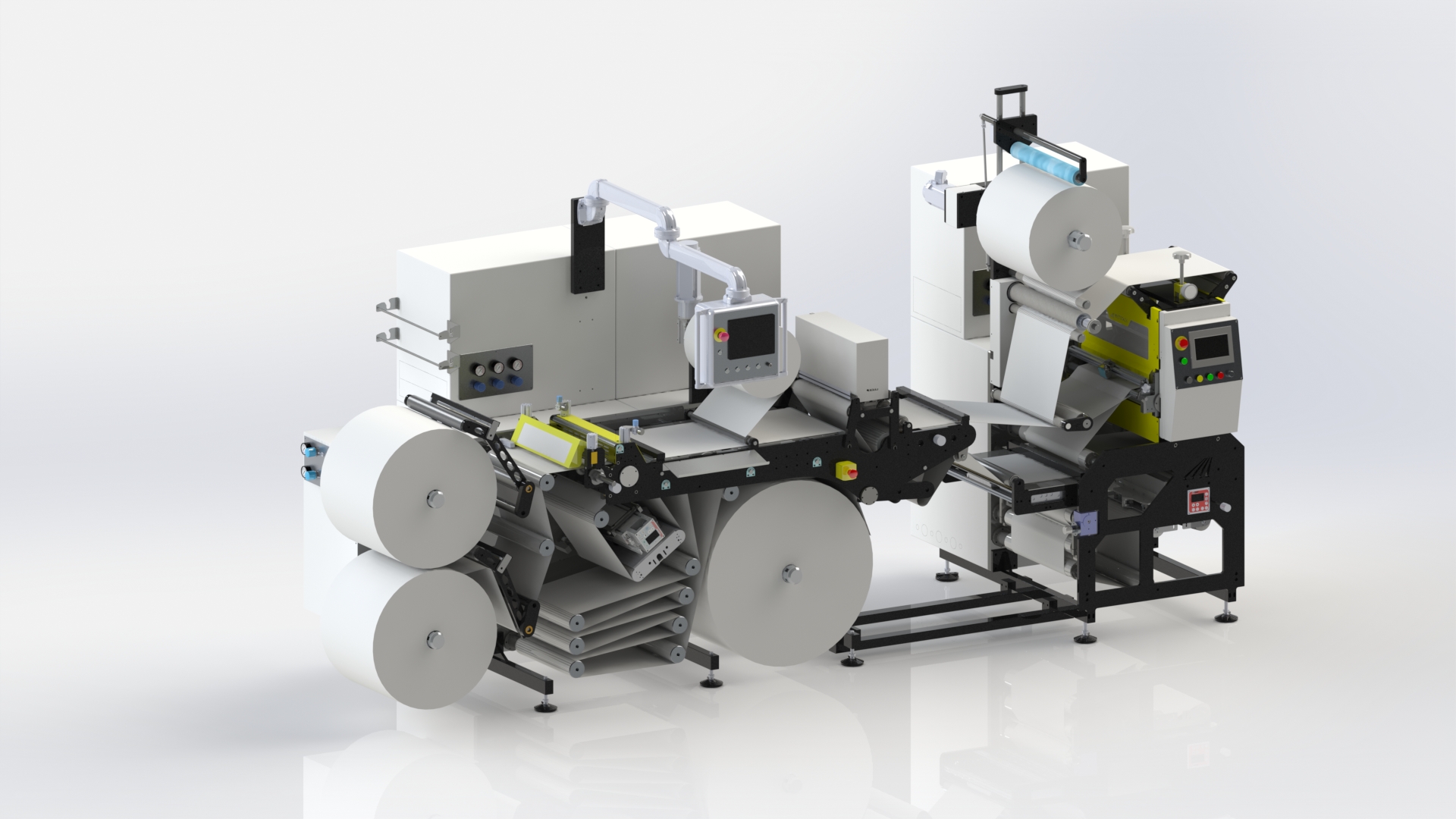

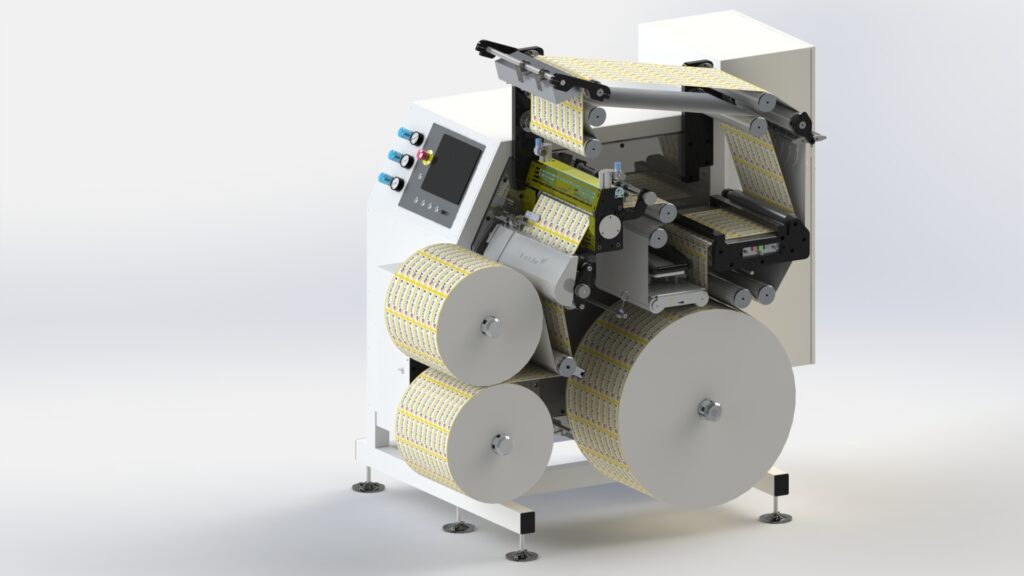

UNWINDER:

- max. roll diameter 800 mm

- max. lifting capacity 160 kg

- pneumatic shaft Ø 76 mm + special system with transport rollers for easy loading of new roll

- US sensor od current roll's diameter ensuring constant tension of the web during the whole production

SPLICE TABLE:

- located above the unwinder

- equipped with pneumatic clamp blocks, thanks to which the tension of the material is retained during webs connection

- additional repair table for separating the defective material

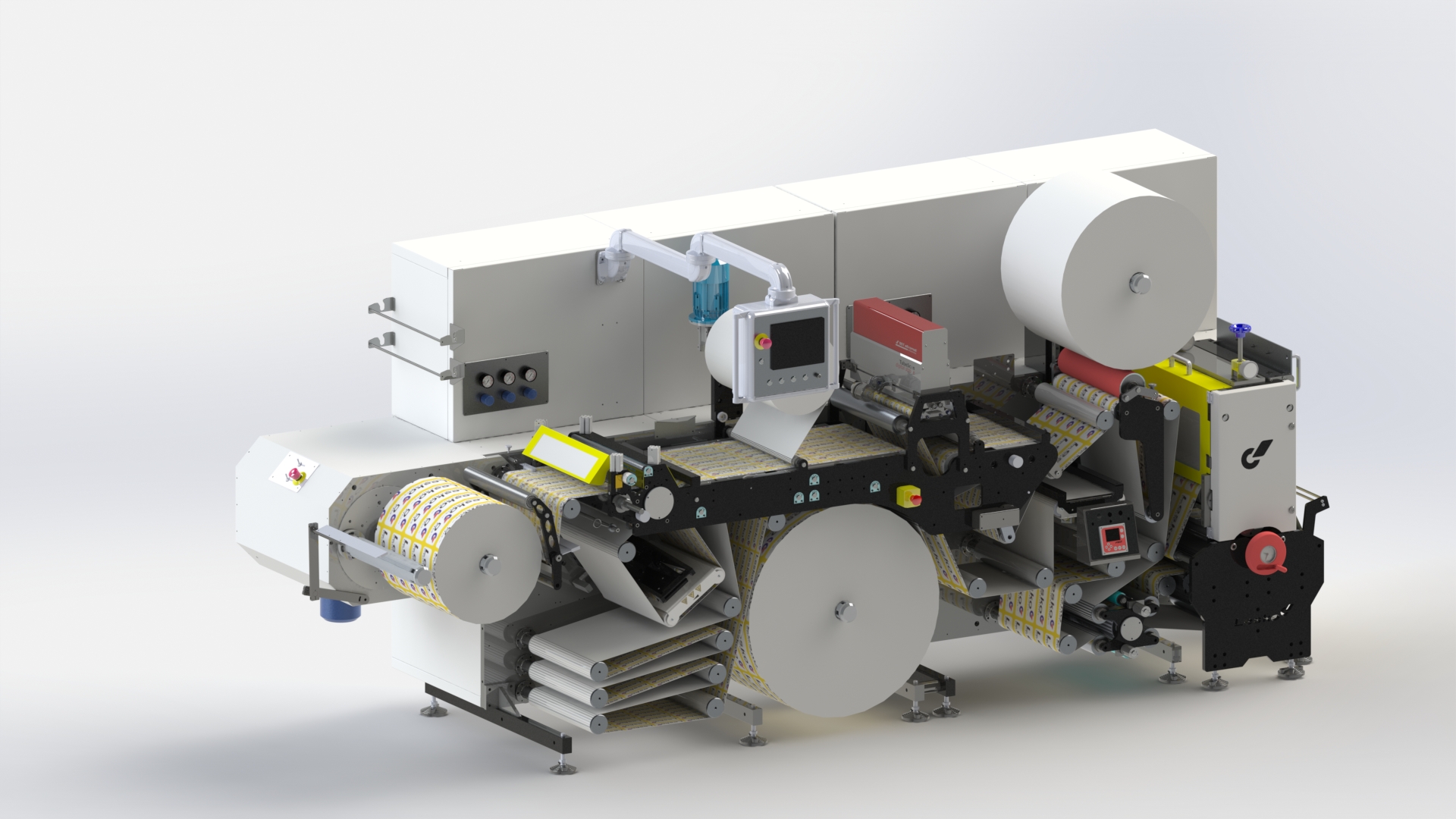

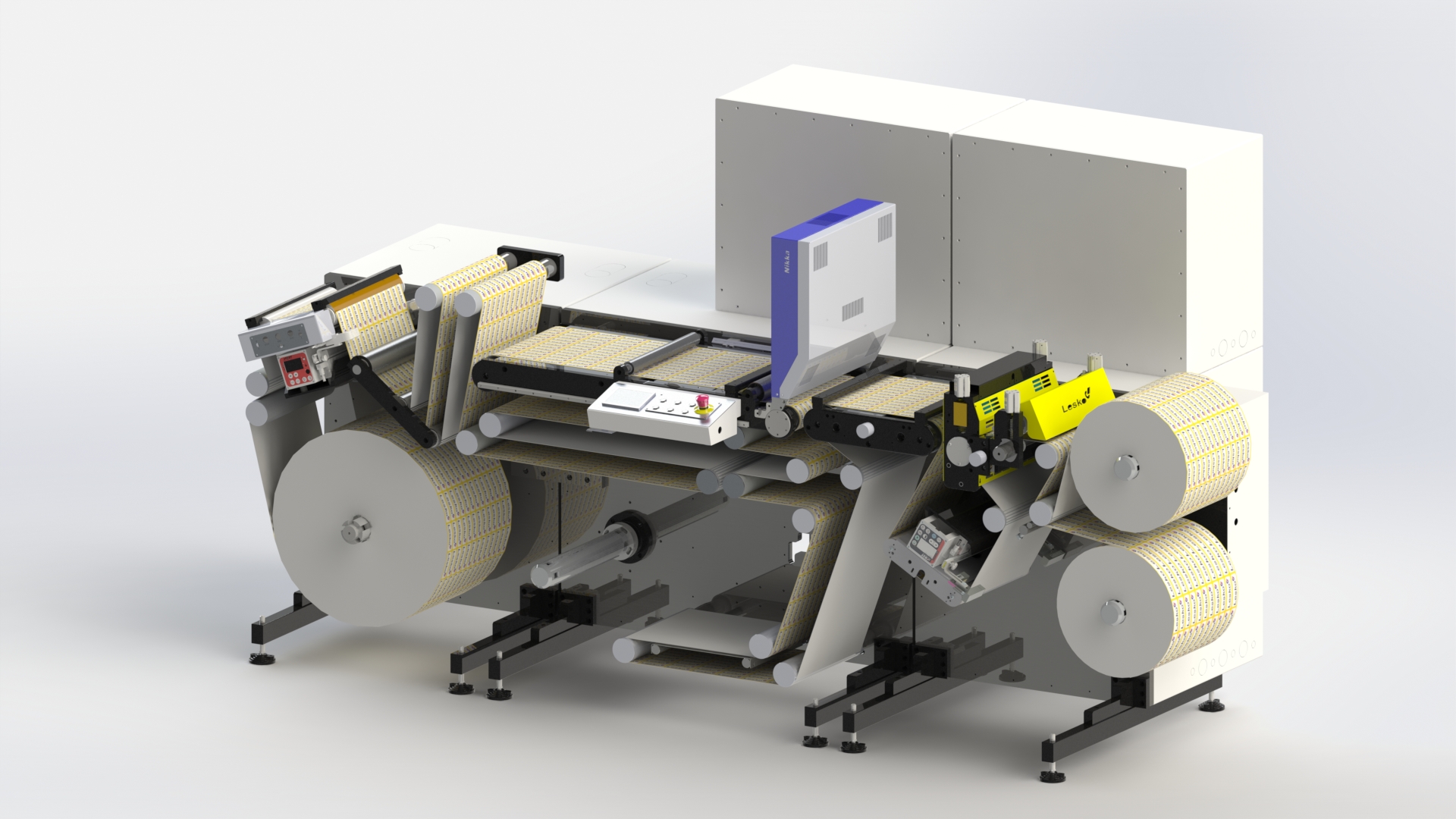

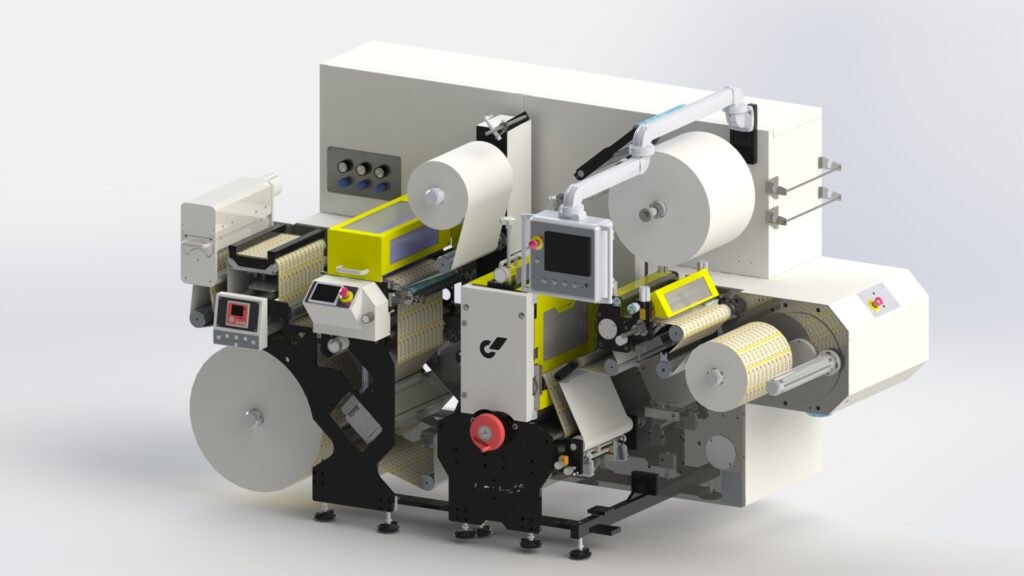

WEB MOTION:

- BST web guide system located before shear cutting knives unit enables precise slitting

NIP-ROLL:

- pneumatic clamp ensuring an equal pressure across the entire width of the roller

- easy replacement and cleaning of rubber roller

SHEAR CUTTING KNIVES UNIT:

- knives for scissor system cutting (type 3G)

- pneumatically inserted and removed

- 3 sets of knives + the possibility to add following

- min. cutting width 20 mm

- easy to remove

REWINDER:

- pneumatic clamp of the web's end

- pneumatic shaft Ø 76 mm

- max. rewinding diameter Ø 600 mm

optional:

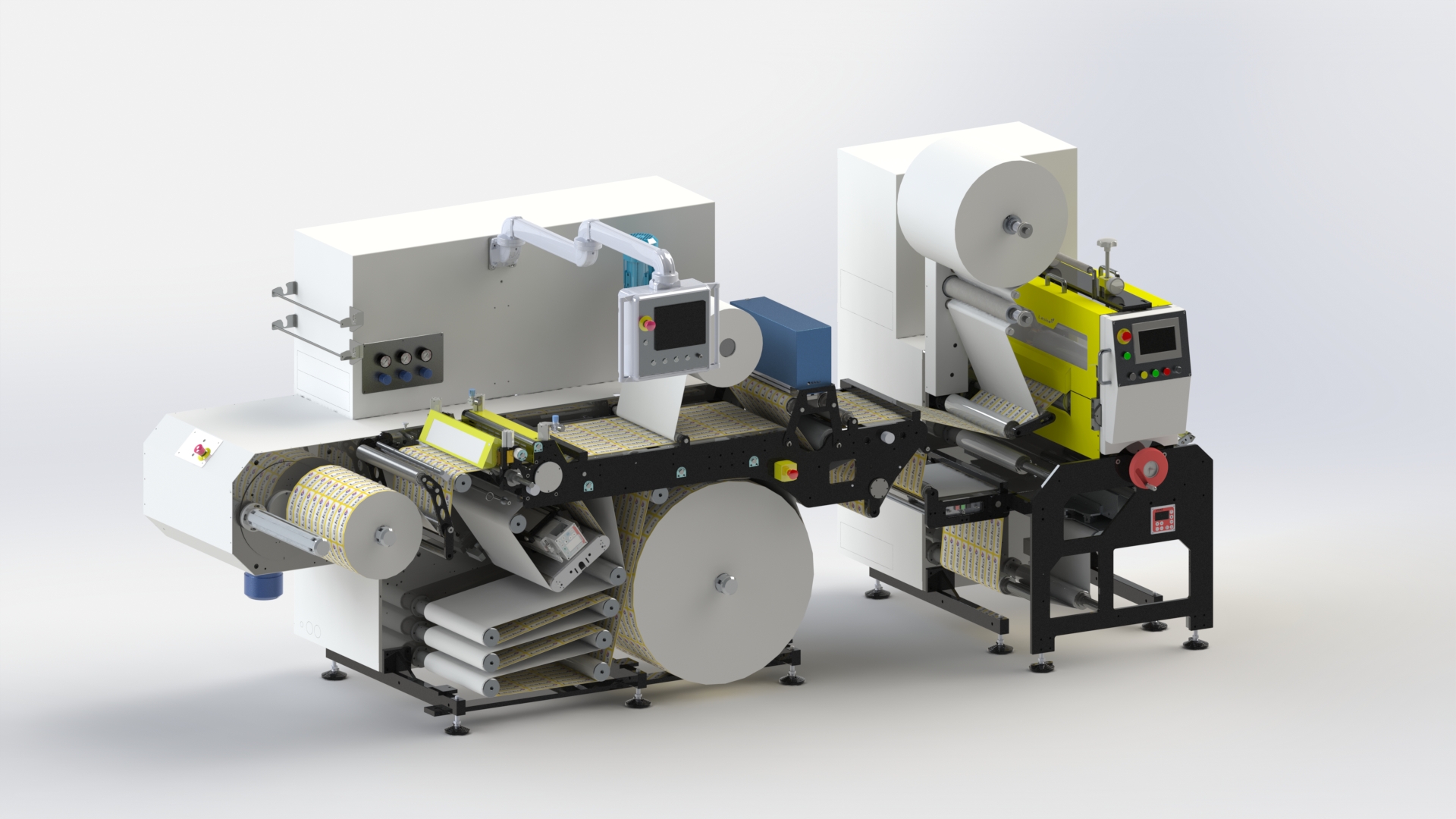

- additional rewinder (max. rewinding diameter on both shafts - Ø 2 x 600 mm)

- additional shafts with diameters from Ø 19 to Ø 76mm

- adapters for shafts with diameters from Ø 76 to Ø 152 mm

- semi-turret version of rewinders with the option of simultaneous rewinding on both shafts

ADDITIONAL EQUIPMENT:

- 100% inspection system (camera for print quality control + touch screen)

- buffer for high speed inspection mode

- system for rewinding of faulty material placed above inspection table

- footswitch for machine's control

- razor blades knives unit:

- 5 knives + possibility to add following

- easy removal and replacement for a different kind of knives

- knives roller pneumatically inserted and removed

- crush cutting knives unit:

- pneumatically inserted and removed

- 3 knives + possibility to add following

- at nip-roll place

- additional rewinder's shafts:

- diameters: Ø 25 mm, Ø 40 mm, Ø 50 mm, Ø 76 mm

- the side waste exhauster