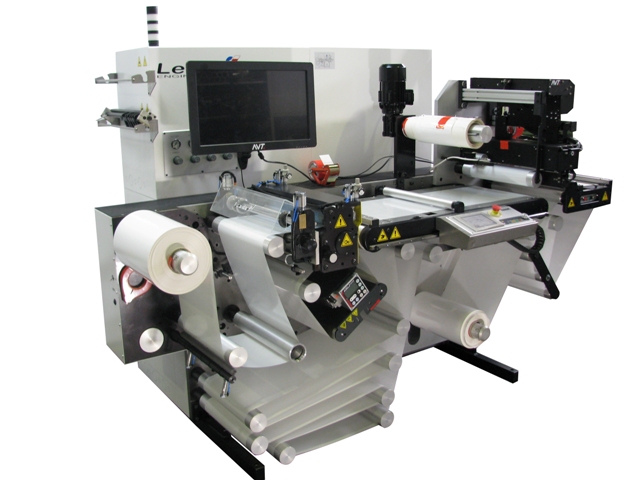

LESKO TT200

Horizontal table rewinder LESKO TT200 is a dedicated solution for rewinding of printed materials from roll to roll.

Machine is useful for verification of the quality, as well as for the correction of wound materials.

Such a device cannot be missed by any printing house.

FEATURES AND OPTIONS

TECHNICAL DATA:

- max. working width 200 mm

- max. speed 400 m/min

- power supply voltage 200-240V / 10A

- frequency 50 Hz (60 Hz optional)

- installed power 1.3 kW

- average air requirement 0.8 l / min

- working pressure 3 bar

- weight 200 kg

- size (L x W x H) 860 x 1110 x 1050 mm

ADVANTAGES:

- compact design

- user friendly interface - intuitive and easy to use

- current meters and labels electronic counter - very precise confectioning

- bidirectional rewinding

- change the direction of rewinding with a single button

- 2 pneumatic expansion spindles (rewinding and unwinding) Ø 76 mm

- the basis for Ink Jet numbering printheads

ADDITIONAL EQUIPMENT:

- easily replaceable pneumatic spindles with diameters from Ø 19 to Ø 76 mm

- adapters for spindle over Ø 76 mm

- sensor for detecting missing labels

- razor blade knives for slitting the web

- stroboscope with a movable arm

- plate for removing the rolls

- lifted table top - additional tension control by changing the angle of inclination of table top; controlled from the panel, run with a single button

- constant speed during rewinding - max. mechanical speed up to 300 m/min

- table with clamps for connecting the webs